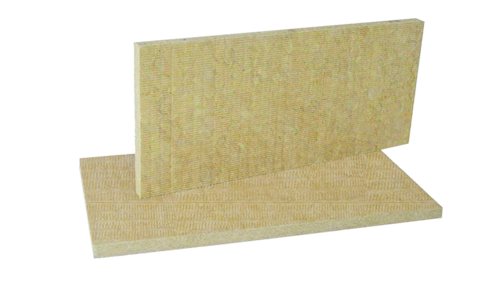

★ Taishi high-end composite slab rock wool products are specially designed and manufactured for the automated production of modern high-end composite slabs. The product has precise geometrical size control, good fiber toughness, high compressive strength, strong shear resistance, good resilience of the sizing roller, heat preservation and heat insulation, sound absorption and noise reduction, fire and moisture resistance, etc. after the cut strip is turned over.

| Product number | Rock wool board | |

| Apparent density (kg/m3) | 100 | 120 |

| Thickness (mm) | 100 | 100 |

| Size (mm) | 1800×1200 | 2400×1200 |

| Other specifications can be customized according to customer requirements. |

| Product performance | unit | TSSB100 | TSSB120 | Standard |

| Apparent density | Kg/m3 | 100 | 120 | |

| Thermal conductivity (25℃) | W(m·K) | ≤0.040 | ≤0.040 | GB/T10295 ASTM C518 |

| Shot content | % | <5%(Coarse slag ball size>0.25mm) <30% (fine slag ball size>63μm) | -- | |

| Combustion performance | -- | A1 | GB/T8624-2006 | |

| Maximum use temperature | ℃ | 600 | ASTM C411 | |

| Linear shrinkage | % | <1 | ASTM C356 | |

| Moisture absorption rate | % | <1 | GB/T11835 | |

| Hydrophobic rate | % | ≥99 | GB/T10299 | |

| Acidity coefficient | -- | ≥1.8 | GB/T5480 | |

| The above data is for reference only, and the company reserves the right to improve product performance with the improvement of production equipment and technology. |

It is mainly used in automatic production processes such as online cutting, automatic turning, and glue curing of high-end composite slabs.

In order to facilitate the use, transportation and storage, the products are stacked in brackets and should be stored in a dry and ventilated room.